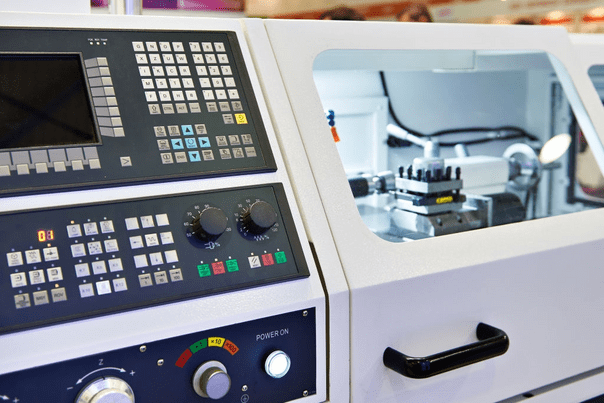

Facilities

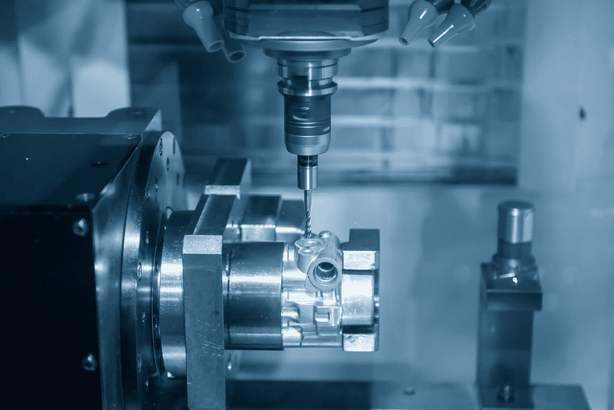

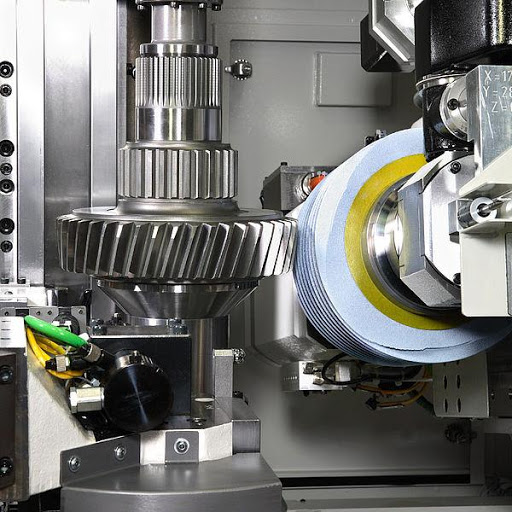

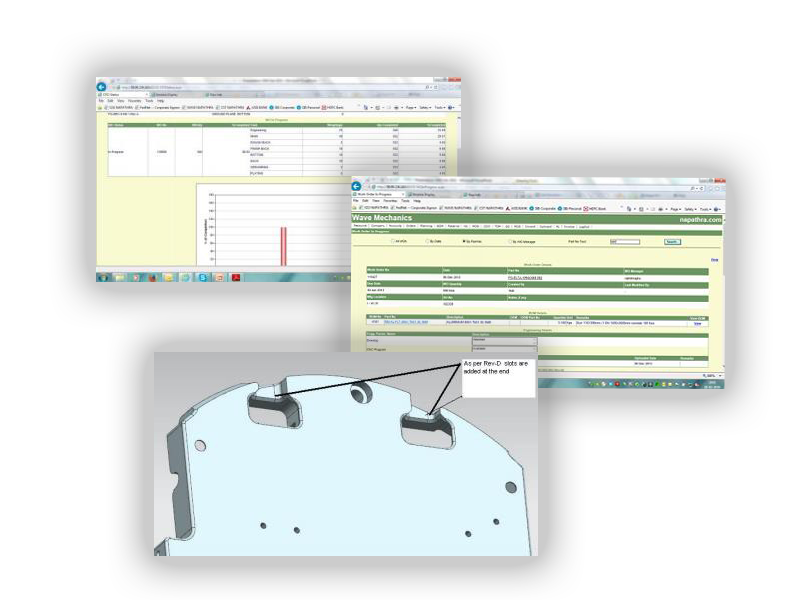

Wave Mechanics is home to world-class machinery & equipment, housed in our facility in Bengaluru, India. We continually invest in innovative manufacturing methods, modern machinery & equipment, human resources, and other associated services to exceed the most demanding customer expectations. Our facility provides advanced capabilities with extensive capacities to support customer needs from a one-off requirement up to volumes of many thousands. Extensive experience with high-mix low-volume manufacturing for large industry players helps us deliver exactly as per customer schedules and quality requirements. Our dedicated project manager will regularly keep you updated on your order status and other information to ensure operational transparency.

Investment into a state-of-art production facility has been designed to ensure world class quality, consistently and on time. Our facility has high-end equipment like tool presetters, heat shrink tool holders, & DNC program software to minimize rejections, accidents & human error. Full power back up via generators & UPS ensures complete utilization of our infrastructure and minimum downtime in our 3 shift operation cycle.